Sunny Diamond Core Drill Bits for Drilling Reinforced Concrete

Basic Info

Model No.: SY-DB-02(Core Drill Bits)

Product Description

Model NO.: SY-DB-02(Core Drill Bits) Bore: 1/2" Gas Type: Completed/Segmented Features: High Tension & Efficiency Characteristic: Long Lifespan Support: OEM & ODM Transport Package: Paper Bag, Poly Bag, Carton Box and Wooden Box Origin: Quanzhou China Diameter(mm): 18-400mm Length(mm): 60-500 Advantage: High Quality Painting Color: as Customer′s Request Company Website: HTTP://Www.Sunnytools.Biz Trademark: SUNNY Specification: Grade A HS Code: 8207501000

Sunny Diamond Core Drill Bits for Drilling Reinforced Concrete

Construction Core Drill Bit

Core drill bit are produced to drill dimensionally accurate bore holes in these materials, reinforced concrete, asphalt,masonry,natural and artificial stone. Widely used in the building,heating,sanitary and electrical industries.

Features:

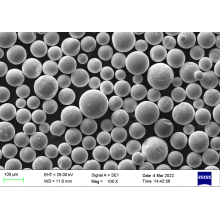

1. high diamond concentration,fast drilling rate,easy cutting and long service life.

2. Pre-sharpened diamond segments provide immediate usability.

Diamond Core Drill Bit--FAQ and Troubleshooting

SUNNY has prepared this guide to help you find, identify and resolve the problems which you may encounter with diamond drill bits. The majority of problems encountered arise from: the use of a drill bit not suited to the job, the incorrect use of a drill bit, equipment faults. The tool will not cut

Sunny Diamond Core Drill Bits for Drilling Reinforced Concrete

Construction Core Drill Bit

Core drill bit are produced to drill dimensionally accurate bore holes in these materials, reinforced concrete, asphalt,masonry,natural and artificial stone. Widely used in the building,heating,sanitary and electrical industries.

Features:

1. high diamond concentration,fast drilling rate,easy cutting and long service life.

2. Pre-sharpened diamond segments provide immediate usability.

| BASIC INFO | |

| Brand | SUNNY |

| Product Name | Sunny Diamond Core Drill Bits for Drilling Reinforced Concrete |

| Item No. | SY-DCD-313 |

| Diameter | 25mm-598mm |

| Material | Diamond |

| Origin | Quanzhou, Fujian, China |

| Features | 1: high diamond concentration,fast drilling rate,easy cutting and long service life. 2: Pre-sharpened diamond segments provide immediate usability. |

| Application | Used for reinforced concrete, asphalt,masonry,natural and artificial stone. |

| Diameter(mm) | Effective length(mm) | Connection | Segment shape |

| φ25~φ598 | L350-L600 | 1.1/4"UNC R 1/2" | spire turbo normal |

Diamond Core Drill Bit--FAQ and Troubleshooting

SUNNY has prepared this guide to help you find, identify and resolve the problems which you may encounter with diamond drill bits. The majority of problems encountered arise from: the use of a drill bit not suited to the job, the incorrect use of a drill bit, equipment faults. The tool will not cut

| Symptom | Cause | Remedy | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

The tool will not cut. |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||