Diamond Wre Saw for Granite Marble Concrete Cutting (S-DWS-1046)

Basic Info

Model No.: S-DWS-1046

Product Description

Model NO.: S-DWS-1046 Manufacturing Arts: Sinter Saw Blade External Diameter: Diamond Wire Saw Bead Number(Mm): 37/40 Line Speed: 18 - 38 Life Span: 0.5 - 45 Certifcate: ISO, BV, ISO 9001:2008 Delivery Time: 7 - 15 Days Specification: SGS, ISO9001: 2008, BV HS Code: 82029910 Kind: Stone Sawing Machine Usage: Stone Cutting Bead Diameter(Mm): 7.2 - 11.5 Fixing Method: Spring/Rubber Cutting Speed: 0.5 -10 Model No.: S-Dws-1046 Brand: Sunny Trademark: SUNNY Origin: Quanzhou China Diamond Wre Saw for Granite Marble Concrete Cutting

Besides Premium Quality Granite Diamond Wire For Granite And Sandstone, we also produce following type:

Diamond wire for marble cutting

Diamond wire saw for Granite quarry

Diamond wire saw for Marble

Diamond wire saw for cutting reinforced concrete

Multi wire saw

1. Use for Granite/sandstone cutting.

2. High quality cable insure less breakage and good tension.

3. Keep Sharp and long life

4. Original Rubber/plastic bring better performance in tough environment

Description:

Diamond wire-saws are widely used for granite quarries. The main specialties of diamond wire-saws are:

· To be able to used for great area granite quarries cutting

· To get high percentage of forming dimension stone

· High manufacture efficiency

· Safety, low- noise, no- dust and friendly surroundings

· Low cutting cost.

The advantage of rubber wire saw for granite quarry:

1. The rubber adheres better to the beads and support cable, which protects it better from the action of abrasive pastes, in particular when the cable takes up small radii of curvature (beginning and end of quarry cuts).

2. The rubber easily withstands increases in temperature caused by badly controlled water spraying, which often happens in a quarry, whereas plastic softens and losses its strength properties.

3. The flexibility of a cable fitted with rubber is greater, which reduces the risk of irregular wearing of the beads (ovalisation phenomenon).

37-75KW wire saw machines are more used for granite quarry, the water spraying between 25-50 L/min according to the cut dimension.

Recommendations:

· The rotation of the wire should be regularly checked.

· The worn condition of beads should be regularly inspected.

· The worn condition of connections & the beads near connections should be regularly checked. Change connections when it's needing.

· The cable tension is set in 250-300kg(Φ 4-5mm cable).

· Adjust the linear speed of the wire according to the material being sawn:

· During the sharpening of a new wire, the liner speed should be reduced 2-3 m/s from the above standard.

· Water requirement is between 15-25L/min.

Kindly Noted, when place order please inform the following:

Diameter of the Wire

Wire Type (rubber or rubber+spring)

Granite Type (Hard, Medium, Soft, or Abrasive)

Quantity (How many Meters)

Wire Saw Machine Power (How many KW or HP of the motor)

Expected cutting speed and life(M2)

Expected shipping date

Contact us if you need more details on Diamond Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Diamond Wire Saw、Diamond Cutting Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

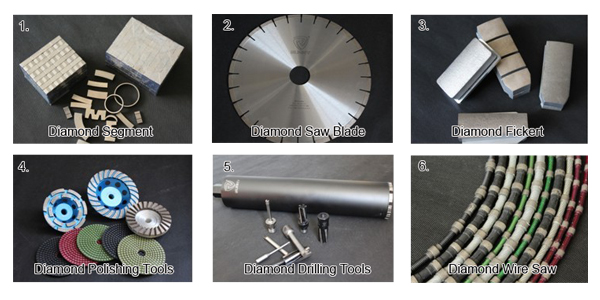

Besides Premium Quality Granite Diamond Wire For Granite And Sandstone, we also produce following type:

Diamond wire for marble cutting

Diamond wire saw for Granite quarry

Diamond wire saw for Marble

Diamond wire saw for cutting reinforced concrete

Multi wire saw

1. Use for Granite/sandstone cutting.

2. High quality cable insure less breakage and good tension.

3. Keep Sharp and long life

4. Original Rubber/plastic bring better performance in tough environment

Description:

Diamond wire-saws are widely used for granite quarries. The main specialties of diamond wire-saws are:

· To be able to used for great area granite quarries cutting

· To get high percentage of forming dimension stone

· High manufacture efficiency

· Safety, low- noise, no- dust and friendly surroundings

· Low cutting cost.

The advantage of rubber wire saw for granite quarry:

1. The rubber adheres better to the beads and support cable, which protects it better from the action of abrasive pastes, in particular when the cable takes up small radii of curvature (beginning and end of quarry cuts).

2. The rubber easily withstands increases in temperature caused by badly controlled water spraying, which often happens in a quarry, whereas plastic softens and losses its strength properties.

3. The flexibility of a cable fitted with rubber is greater, which reduces the risk of irregular wearing of the beads (ovalisation phenomenon).

37-75KW wire saw machines are more used for granite quarry, the water spraying between 25-50 L/min according to the cut dimension.

Recommendations:

· The rotation of the wire should be regularly checked.

· The worn condition of beads should be regularly inspected.

· The worn condition of connections & the beads near connections should be regularly checked. Change connections when it's needing.

· The cable tension is set in 250-300kg(Φ 4-5mm cable).

· Adjust the linear speed of the wire according to the material being sawn:

· During the sharpening of a new wire, the liner speed should be reduced 2-3 m/s from the above standard.

· Water requirement is between 15-25L/min.

Kindly Noted, when place order please inform the following:

Diameter of the Wire

Wire Type (rubber or rubber+spring)

Granite Type (Hard, Medium, Soft, or Abrasive)

Quantity (How many Meters)

Wire Saw Machine Power (How many KW or HP of the motor)

Expected cutting speed and life(M2)

Expected shipping date

Contact us if you need more details on Diamond Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Diamond Wire Saw、Diamond Cutting Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

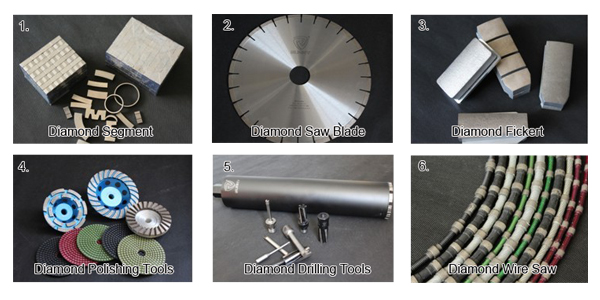

Product Categories : Diamond Wire Saw

Premium Related Products

Other Products

Hot Products

Diamond Tools for Grinding and Polishing Concrete FloorItaly Quality Diamond Core Drill Bit (SCMD-01)Diamond Core Drill Bit Segment for Concrete DrillingSunny Tools Long Life Fickert Grinding Stone DiamondWet Diamond Blades for Concrete CuttingSuper Hard Diamond Metal Bond Router Edge Grinding WheelBush Hammer for Marble and Granite (SY-BH-T001)300-800mm Diamond Concrete Blade, Diamond Reinforce Concrete Saw Blade, Diamond Disc (SY-DISC-T001)Diamond Segment Saw Blade Cutting Segment (SN-8)Italy Quality Diamond Finger Bit for Granite Marble Milling (SN-9)Diamond Wire Saw for Stone, Concrete Cutting (SN-11)Edge Cutting Diamond Blade Segment (SN-12)Sunny Diamond Saw Blade, Diamond Cutting Disc (SY-DSB-008)100mm Diamond Polishing Pads for Granite & Marble (SY-PL-T001)Stone Concrete Grinding Polishing Diamond Cup Wheel (SY-DCW-1000)High Quality Diamond Cutting Disc for Marble and Granite